TV WEALTETY

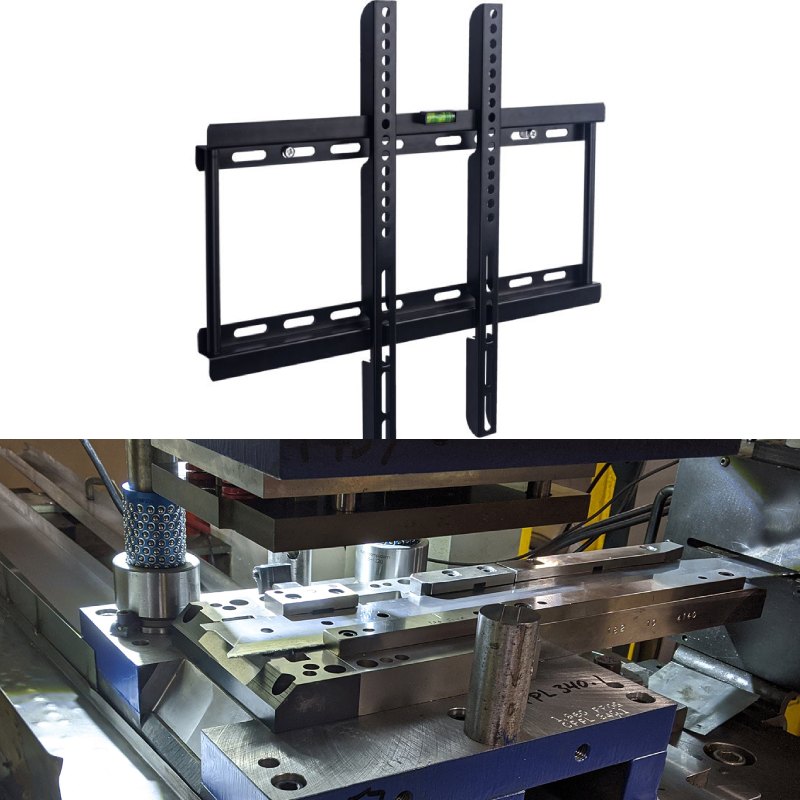

Huaner jest profesjonalnym producentem przedziałów ściennych telewizyjnych. Nasze uchwyty ścienne LCD mają wzmocnione stalowe płyty stalowe dla bezpieczeństwa sprzętu. Korzystając z 200-tonowego ciągłego składania matrycy, produkujemy 3000 sztuk dziennie. Nasze wsporniki montażowe telewizyjne mogą być używane do montażu oznakowania cyfrowego, kiosków informacyjnych, terminali samoobsługowych i sprzętu medycznego. Oferujemy usługi OEM/ODM z dostosowanymi specyfikacjami, materiałami, kolorami, logo itp.

Wyślij zapytanie

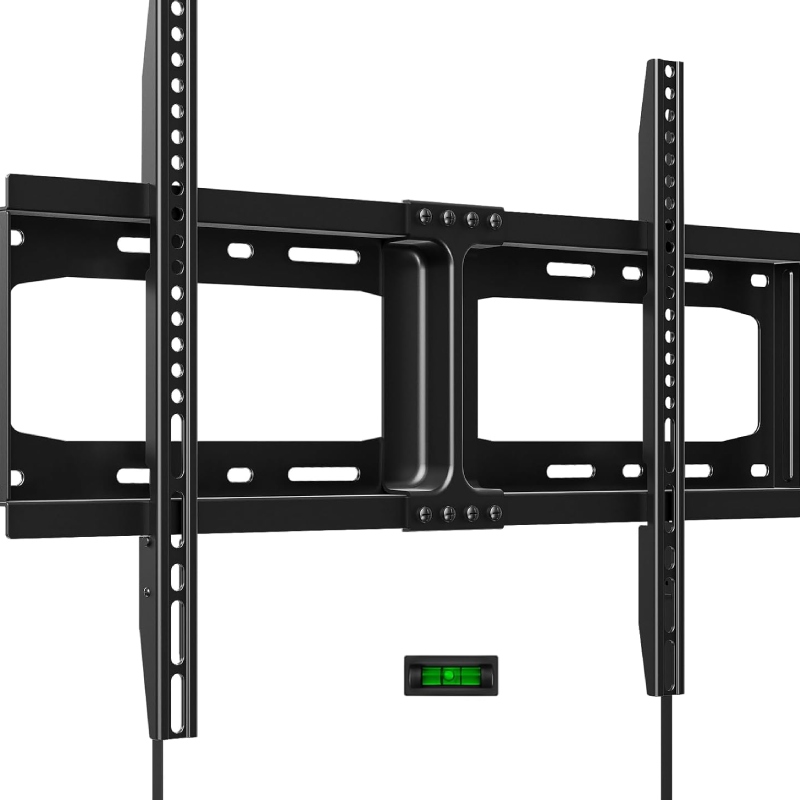

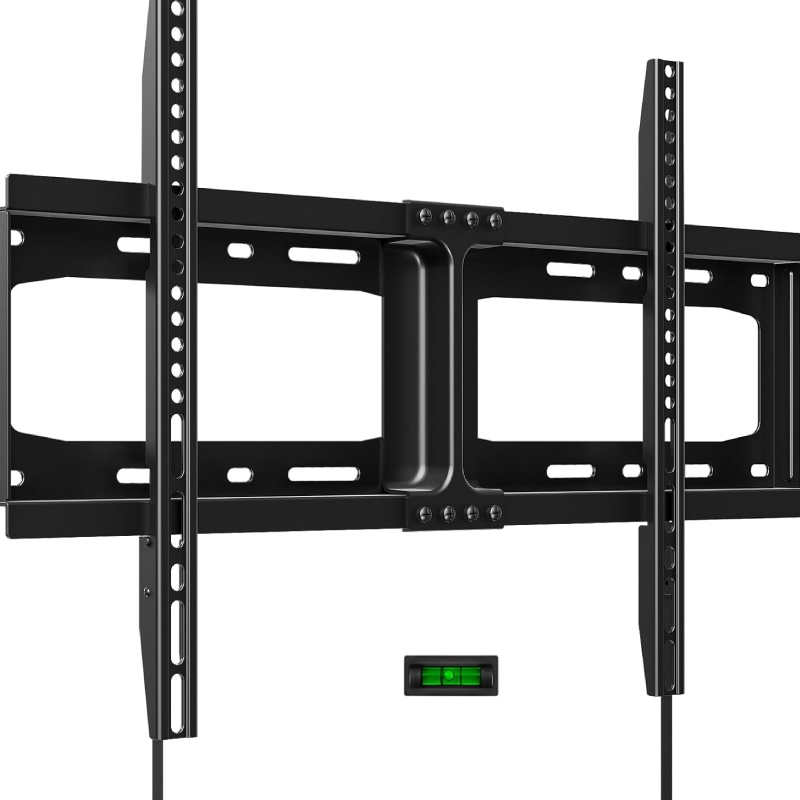

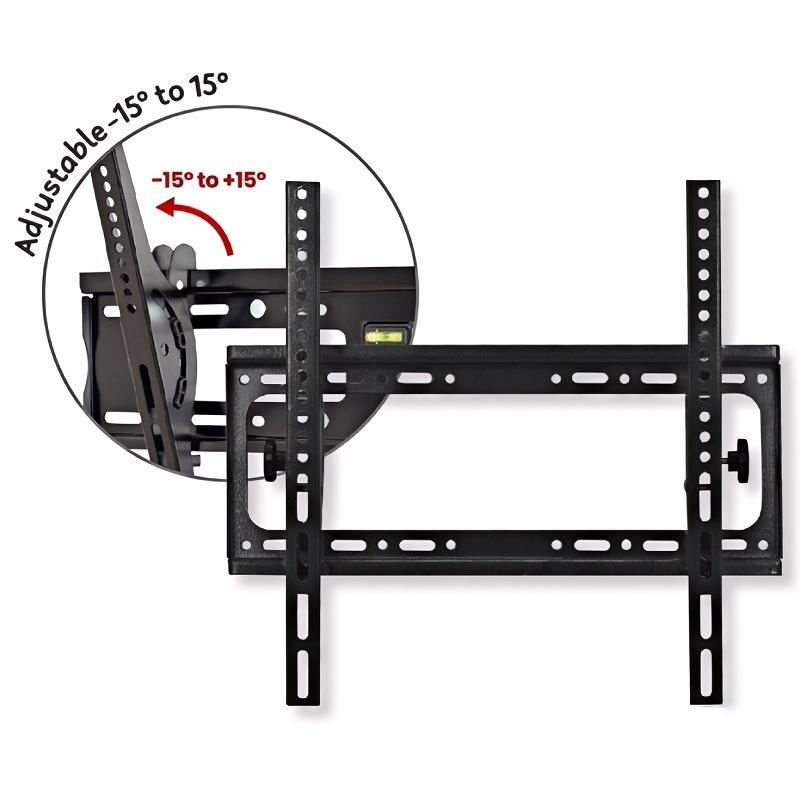

TV Wall Bracket is made of durable 1.8mm SPCC cold-rolled steel that resists bending. It's precisely manufactured using 200-ton stamping technology with tight ±0.15mm tolerances. The screen TV wall mount fits TVs from 17 to 37 inches and supports all standard VESA patterns (75x75mm to 800x400mm), making it widely compatible. The surface treatment of the television wall bracket has triple protective coatings: electrogalvanizing, epoxy spraying, and passivation. The bracket can be used in classrooms, living rooms, conference rooms, hotel lobbies and other settings, securely wall-mounting your TV equipment. The LCD stand bracket has passed the 96-hour salt spray test for long-lasting corrosion and rust resistance; it is also CE/ROHS compliant. The TV steel wall fixing supports LOGO stamping (0.5mm accuracy) and RAL color standard spraying customization to meet brand personalization needs.

Materials and Processes

- Stamping process: 200-ton progressive die stamping (7 stations), tolerance ±0.15mm, TV wall brackets daily production capacity 3,000 pieces

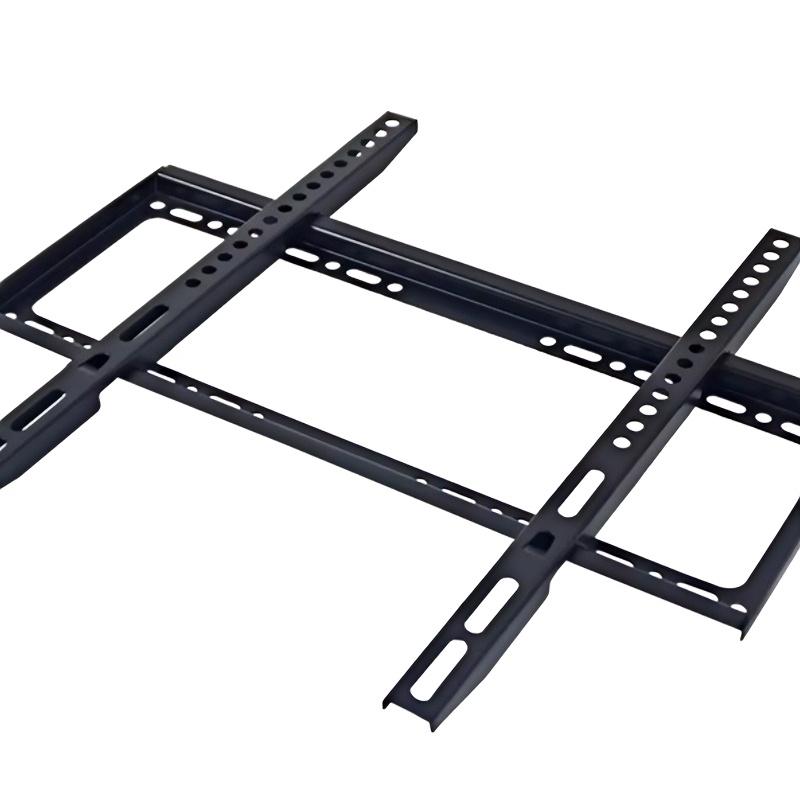

- Base material: 1.8mm SPCC cold-rolled steel (Japanese standard JIS G3141), yield strength ≥270MPa

- Structural reinforcement: X-shaped reinforcement rib stamping design, torsional rigidity increased by 45%

- Triple protection: 8μm electroplated zinc coating → 60μm epoxy powder spraying → chromate passivation, with corner TV brackets passed 96h neutral salt spray test (GB/T 10125)

- Edge processing: Fully automatic CNC chamfering, fillet radius ≤0.3mm (EN ISO 13715 industrial safety standard)

Application

Hotel digital signage system: TV wall brackets are used for lobby information screens, guest room guide screens, and elevator bay ad displays.

Enterprise multimedia conference rooms: video conferencing terminals, collaborative office screens, and remote control consoles

Smart teaching equipment for educational institutions: interactive smart blackboards, electronic whiteboards, and multimedia podiums

Medical equipment suspension system: TV wall mount brackets are used for operating room monitoring screens, diagnostic report terminals, and ward infotainment terminals.

Public facility self-service terminals: subway ticket machines, bank ATMs, and airport check-in kiosks

Customization

Surface treatment: The TV wall brackets offer anodizing (RAL color chart), fluorocarbon coating(PVDF) or nickel-plating with brushed finish

Mold development: Providing DFM analysis report, with customer LOGO stamping (minimum 0.5mm stamping precision)

Packaging solution: Impact-resistant EPE lining + stackable blister tray, achieving 35% higher single-box loading capacity

Process Comparison

| | TV wall bracket (Stamping Process) | Competitor (Welding Process) | Advantage Analysis |

| Production Process | Integrated stamping molding | Cutting + Welding + Assembly | Reduced seams, enhanced structural stability |

| Production Efficiency | 12 seconds/piece (continuous stamping) | 45 seconds/piece (multi-process collaboration) | Efficiency increased by 275%, suitable for bulk orders |

| Corrosion Resistance | 96 hours salt spray resistance | 48 hours until oxide spots appear | Superior surface coating/plating process, doubled lifespan |

| Order Flexibility | MOQ 100 sets (72-hour delivery) | MOQ 500 sets (15-day delivery) | Quick response, suitable for small batch customization |

| Cost Control | Low unit cost for flat TV wall mounts cost after mold amortization | High manual welding cost proportion | Significant marginal benefits from large-scale production |